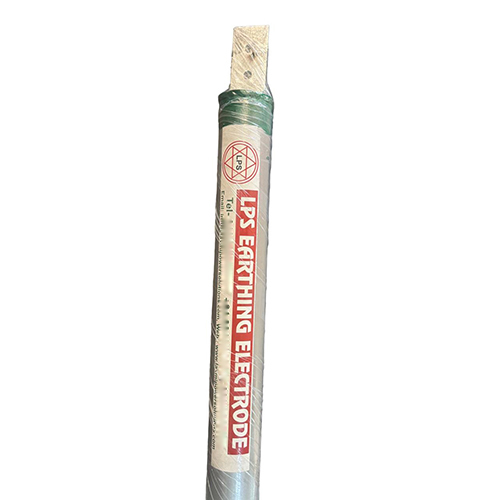

Maintenance Free Earthing Electrode

2500.0 INR/Set

Product Details:

- Purity 99%

- Diameter 50 Millimeter (mm)

- Copper Thickness 250 Micrometers (um)

- Life Span Long Life

- Product Type Maintenance free Chemical Earthing

- Material Galvanized Steel

- Application Earthing

- Click to View more

X

Maintenance Free Earthing Electrode Price And Quantity

- 2500.0 INR/Set

- 1 Set

Maintenance Free Earthing Electrode Product Specifications

- 0.5 Millimeter (mm)

- 250 Micrometers (um)

- Long Life

- Galvanized Steel

- Silver

- 3000 Millimeter (mm)

- Plain

- 99%

- Maintenance free Chemical Earthing

- 50 Millimeter (mm)

- Cylindrical

- Yes

- Earthing

- highly conductive, Maintenance free grounding system

Maintenance Free Earthing Electrode Trade Information

- Cash in Advance (CID)

- 500 Set Per Month

- 15 Days

- No

- Contact us for information regarding our sample policy

- As per the Situation.

- All India

- ISO, CE, CPRI, ROHS, NABL etc.

Product Description

Maintenance Free Chemical earthing is a method used to ground electrical equipment and systems. Its primary purpose is to provide a low resistance path for the dissipation of electrical energy to the earth.

A chemical earthing system consists of an earth electrode made of copper, galvanized steel or a mixture of both with a backfill material of a compound made of conductive minerals, with carbon as one of the major components. The backfill compound is mixed with water, and the mixture is poured into a borehole dug into the soil. The earth electrode is then inserted into the borehole and covered with more of the compound. This creates a low resistance path to the earth for electrical currents.

Chemical earthing plays a critical role in protecting electrical equipment and systems from electrical surges or lightning strikes. A well-installed chemical earthing system ensures the safety of the people working with electrical equipment, as well as preventing electrical equipment from exploding or catching fire.

One significant advantage of chemical earthing is that it provides a stable ground resistance, which is essential for the proper functioning of electrical equipment. A stable ground resistance ensures that electrical equipment receives the correct voltage and current, which helps to extend the lifespan of the equipment.

It is important to note that the design and installation of a chemical earthing system must comply with industry standards to ensure its effectiveness. Regular maintenance and testing of the system must also be scheduled to guarantee its proper functioning.

At Laxmi Power Solutions, we provide state of the art chemical earthing solutions to all sectors of the electrical industry. Our team of experts ensures the proper design, installation, and maintenance of chemical earthing systems. Contact us today to learn more about how we can help secure your electrical equipment and systems through our chemical earthing solutions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese